Selected project samples

There are no results that match your selected filter criteria.

Drainage Master Plan Altenburg, Germany

Drainage Master Plan Altenburg, Germany  Extension of the Water Supply of the City of Kabul, Afghanistan

Extension of the Water Supply of the City of Kabul, Afghanistan  New Weir and Hydropower Plant at Rheinfelden, Germany

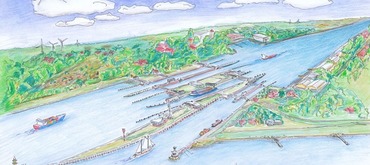

New Weir and Hydropower Plant at Rheinfelden, Germany  Construction of the 5th lock at Brunsbüttel, Germany

Construction of the 5th lock at Brunsbüttel, Germany  General Overhaul of the Weida Dam, Germany

General Overhaul of the Weida Dam, Germany  Developing Waste Management Systems for Priority Areas in Peru

Developing Waste Management Systems for Priority Areas in Peru  Potable Water Treatment Plant “El Milagro” in Tumbes, Peru

Potable Water Treatment Plant “El Milagro” in Tumbes, Peru  Master Plan for Water Recycling for the City of Riyadh, Saudi Arabia

Master Plan for Water Recycling for the City of Riyadh, Saudi Arabia  Groundwater Modelling within the Framework of the Raise of the Impounding Heads at the Weir Structure Bertoldsheim / Danube, Germany

Groundwater Modelling within the Framework of the Raise of the Impounding Heads at the Weir Structure Bertoldsheim / Danube, Germany  Rehabilitation of the Kerosene Damage at the Former NATO Airfield Lahr, Germany

Rehabilitation of the Kerosene Damage at the Former NATO Airfield Lahr, Germany  Rehabilitation of the Coal Mine Complex in Mostar for the Reduction of CO2 Emissions by Coal Seam Fires, Bosnia and Herzegovina

Rehabilitation of the Coal Mine Complex in Mostar for the Reduction of CO2 Emissions by Coal Seam Fires, Bosnia and Herzegovina  Culvert "Wilde Weißeritz" at the Hydropower Plant Tharandt, Germany

Culvert "Wilde Weißeritz" at the Hydropower Plant Tharandt, Germany  Wastewater Collection and Treatment - Bihac, Bosnia and Herzegovina

Wastewater Collection and Treatment - Bihac, Bosnia and Herzegovina  Sewage Treatment Plant of Beni-Mellal, Morocco

Sewage Treatment Plant of Beni-Mellal, Morocco  Waste Treatment Plants in Son La and Soc Trang, Vietnam

Waste Treatment Plants in Son La and Soc Trang, Vietnam  Combined Main Sewer in Torgau-West, Germany

Combined Main Sewer in Torgau-West, Germany  Mobility Concept for the Urban District “Garden Campus Vaihingen”, Stuttgart, Germany

Mobility Concept for the Urban District “Garden Campus Vaihingen”, Stuttgart, Germany  External Monitoring and Geotechnical Consultation for the Sludge Disposal Sites at Francop and Feldhofe in Hamburg, Germany

External Monitoring and Geotechnical Consultation for the Sludge Disposal Sites at Francop and Feldhofe in Hamburg, Germany  Cost Reduction Potentials in Offshore Wind Power in Germany

Cost Reduction Potentials in Offshore Wind Power in Germany  Technical Support for the Offshore Wind Farm Hohe See, 100 km North of the Island of Borkum, Germany

Technical Support for the Offshore Wind Farm Hohe See, 100 km North of the Island of Borkum, Germany  Tender Management for the ST³ Offshore sp.z.o.o. Wind Farm Race Bank in Stettin, Poland

Tender Management for the ST³ Offshore sp.z.o.o. Wind Farm Race Bank in Stettin, Poland  Rehabilitation of the Bank Wall Lotsekanal in Hamburg, Germany

Rehabilitation of the Bank Wall Lotsekanal in Hamburg, Germany  Renovation of the Quay Wall of the Bahnhofskanal in Hamburg, Germany

Renovation of the Quay Wall of the Bahnhofskanal in Hamburg, Germany  Reform of the Subsoil Law in Tajikistan

Reform of the Subsoil Law in Tajikistan